trait

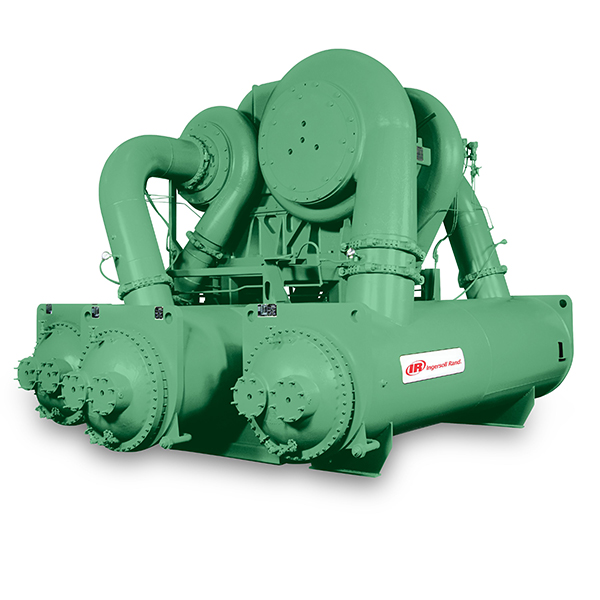

MSG® Integrated gear centrifugal compressor

MSG (Multistage gear) compressors offer excellent design flexibility. MSG compressors are specifically designed for applications in a wide range of configurations to choose from:

Flow rates from 70 to 3800 m3/min (2500 to 135,000 CFM)

Input capacity of 18,650 kW (25,000 hp) or more

Discharge pressure up to 100 barg (1450 psig)

peculiarity

Oil-free air and gas

Prevent system contamination

Reduce the probability of compressed air pipeline fire caused by oil entrainment

There is no costly waste disposal associated with oil-containing condensate

Eliminates the expense and maintenance costs of oil separation filters at discharge locations

High reliability

MSG centrifugal compressors use a more reliable design, all from:

Robust high quality gear design

Long life gear bearing design

Absorb thrust load at low speed

Stainless steel compression element

Low compressor life cycle cost

Compared to positive displacement or other centrifugal compressors, MSG centrifugal compressors have better overall efficiency.

Excellent efficiency under full load, partial load and no load

Low maintenance cost

Increased uptime through highly reliable design (reducing the need to install multiple units for reliability reasons)

There are no sliding or friction parts that can cause wear and loss of efficiency during compression

Easy to operate/maintain

More advanced MAESTRO control system

It works automatically under any operating conditions

Machine self-diagnosis

Compression components do not wear out or require regular replacement

Horizontal split gear box for easy access

Removable intercooler and rear cooler bundle for easy cleaning

Simple installation

Compressors, lubricating oil systems, intercoolers, "couplings", "coupling shields", "interstage piping, etc.", all located on a common base

Easy to install, no special basic requirements

Easy component servicing

Field connection point flexibility

Reduce the space required

The dynamic compression process is pulsation-free, so there is no need to install additional damping equipment.

Apply

Engineering air application

Industrial gas

Instrument air

American Petroleum Institute (API) standards

Blow an airplane

Large factory air

Power industry related

Gas compressor application

Fuel starting

Gas gathering

Hydrocarbon refrigeration gas

Carbon monoxide

CO2 (wet or dry)

SynGas

Low molecular weight circulating gas

High-pressure nitrogen

Landfill gas

Scan line consultation

Scan line consultation